Nd YAG

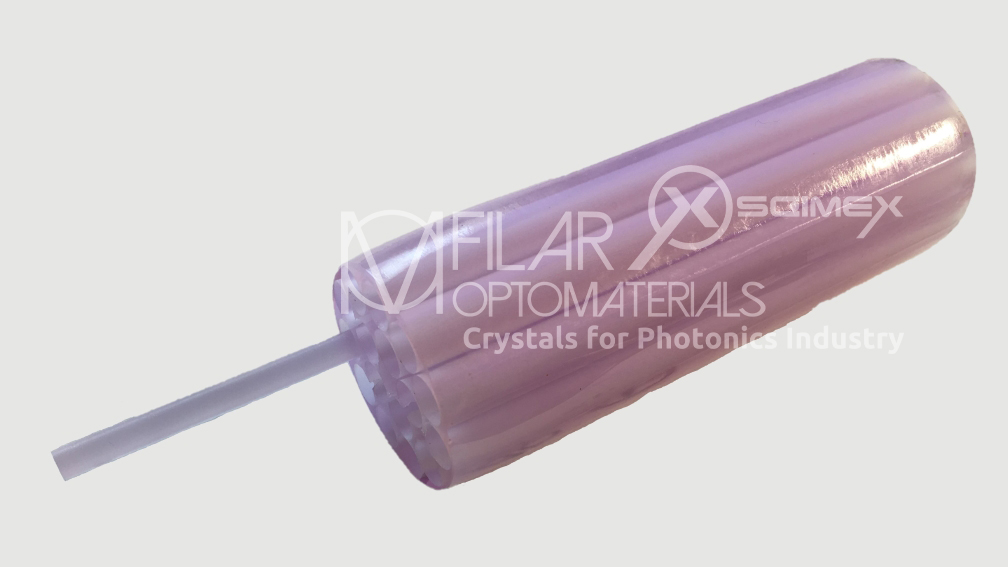

Rod standard variable specifications

Nd doping : 0.1 – 1.5 % ± 0.01 %

Diameter : 2 – 12.7 ± 0.025 mm

Lenght : 5 – 150 ± 0.5 mm

Parallelism : < 10 arc seconds

Perpendicularity : < 5 arc minute

Chamfer : 0.2 mm +0.05 / -0.1mm @45° ± 5°

Flatness : < λ/10 wave @633nm

Scratch/dig : 10 – 5

Trasmitted wavefront deformation (per inch of rod lenght @633 nm) : < 0.25 λ

Extinct ratio : > 25dB @633nm

Traceability : laser-marked S/N on cylindrical surface

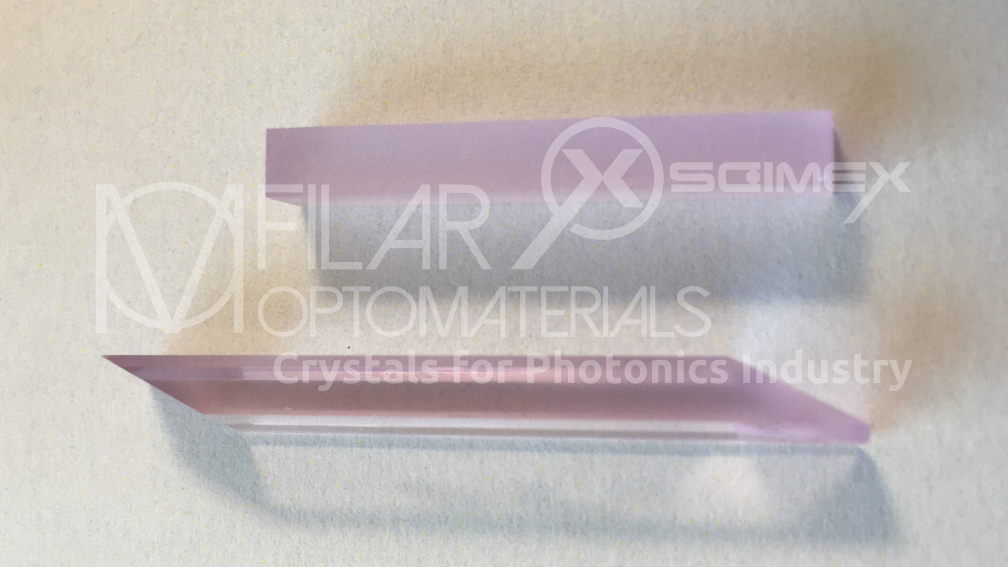

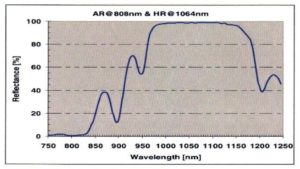

Standard Coating :

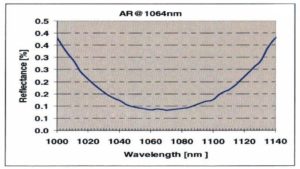

Anti-reflection = R<0.15% @1064nm; R<0.25% @808+1064nm

High-reflection = R>99.9% @1064nm; T>95%@808nm

AOI 0° – 45°

Other special custom coatings are also available.

PHYSICAL PROPERTIES

Nd doping level : 0.1 – 1.5 ± 0.01 at%

Chemical formula : Y3-x Ndx Al5O12

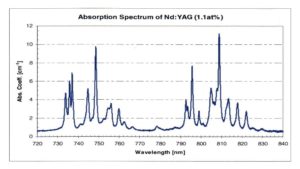

Primary diode pump band : 808.6

Molecular weight : 595.3 g/mole

Crystal structure : Cubic / garnet

Lattice constants: 12.01 Å

Melting point : 1970 °C

Density : 4.55 g/cm3

Mohs hardness : 8.5 @ 20 °C

OPTICAL PROPERTIES

Reflective index (n): 1.817 @ 1064 nm

Lasing wavelengths (λ) : 1064

Primary diode pump band: 808.6 nm

Fluorescence lifetime: 235 μs @ 1.0 at% Nd

THERMAL PROPERTIES

Thermal conductivity : 13W/(cm•K)

Specific heat : 0.59 J/(g•K)

Linear expansion coefficient:

8.2 × 10-6 / K <100>

7.7 × 10-6 / K <110>

7.8 × 10-6 / K <111>

Dissipative fracture limit : ∼ 200 W/cm

Thermal optical coefficient (dn/dT) : +8.0 × 10-6 / K

Among solid-state laser crystals, Nd:YAG is the most versatile and suitable for a wide range of applications due to its physical properties, low threshold, high gain and narrow linewidth. Typical applications include the military, medicine material processing industries for cutting, welding, drilling, marking and repairing.

Nd:YAG lasers are also employed in application areas characterized by harsh environmental conditions, like remote sensing, ocean and atmospheric experiments.

Ultra-pure gas and superior raw material purity, together with a tightly controlled proprietary process, allow Filar Optomaterials to proudly offer premium grade Nd:YAG crystal rods with low losses and superior efficiency .

Nd concentration uniformity along each rod is achieved by using only a small portion (about 20%) of the melt. A very uniform Nd profile is certified for each boule, that is also marked with laser for identification.

Rods with low wavefront distortion are obtained by carefully mapping the boule with double pass interferometer to identify the low stress regions.

In house coating allows a short cycle time after end polishing, assuring high adherence and contamination-free layers.

Controlled environment and process from raw materials to final packaging result in a stable and reliable compositional crystal quality. Particularly, our IR-free rods assure a long term stability to the laser system.